Plastic Screw-in Vent Valve

| PHYSICAL PROPERTIES | REFERED TEST STANDARD | UNIT | TYPICAL DATA |

| Thread SPEC

|

/ |

/ |

M8*1.25-10 |

| Valve Color

|

/ | / | Black/White/Gray

|

| Valve Material

|

/ | / | Nylon PA66

|

| Seal ring Material

|

/ | / | Silicone Rubber

|

| Membrane Construction

|

/ | / | PTFE/PET non-woven |

| Membrane Surface Property | / | / | Oleophobic/Hydrophobic |

| Typical Air Flow Rate

|

ASTM D737 |

ml/min/cm2 @ 7KPa | 2000 |

| Water Entry Pressure

|

ASTM D751 |

KPa dwell 30 sec | ≥60 |

| IP Grade

|

IEC 60529 |

/ | IP67/IP68 |

| Water Vapor Transmission Rate | GB/T 12704.2 (38℃/50%RH、) | g/m2/24h | >5000 |

| Service Temperature

|

IEC 60068-2- 14 |

℃ | -40℃ ~ 125℃ |

| ROHS

|

IEC 62321 |

/ | Meet ROHS Requirements

|

| PFOA & PFOS

|

US EPA 3550C & US EPA

8321B |

/ |

PFOA & PFOS Free

|

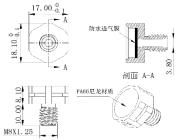

1) The Installation hole size adopts the general standard of M8*1.25.

2) It is recommended to fix the cavity with nuts when the wall thickness of the cavity is less than 3mm .

3) When it needs to install two breathable valves, it’s suggested that the valves should be installed in opposite directions to reach the air convection effects.

4) Suggested installation torque is 0.8N.m, lest torque too much to affect the product performance .

Changing harsh environmental conditions cause seals to fail and allow contaminants to damage sensitive electronics.

AYN® Screw-In Breathable Valve effectively equalize pressure and reduce condensation in sealed enclosures, while keeping out solid and liquid contaminants. They improve the safety, reliability and service life of outdoor electronic devices. AYN® Screw-In Breathable Valve is designed to provide Hydrophobic/Oleophobic protection and withstand the mechanical stresses of challenging environments.

Shelf life is five years from the date of receipt for this product as long as this product is stored in its original packaging in an environment below 80° F (27°C) and 60% RH.

All data above are typical data for the membrane raw material, for reference only, and should not be used as special data foroutgoing quality control.

All technical information and advice given here is based on Aynuo’s previous experiences and test results. Aynuo gives this information to the best of its knowledge, but assumes no legal responsibility. Customers are asked to check the suitability and usability in the specific application, since the performance of the product can only be judged when all necessary operating data are available.