Vent Plug for Pesticide Packaging Barrels

| PHYSICAL PROPERTIES | TEST METHOD | UNIT | TYPICAL DATA |

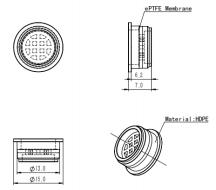

| Plug Material

|

/ |

/ |

HDPE

|

| Plug Color

|

/ | / | White

|

| Membrane Construction

|

/ | / | PTFE/PO non-woven |

| Membrane Surface Property

|

/ | / | Oleophobic & Hydrophobic |

| Typical Air Flow Rate

|

ASTM D737 | ml/min @ 7KPa | 1200 |

| Water Entry Pressure

|

ASTM D751 |

KPa dwell 30 sec | ≥70 |

| IP Grade

|

IEC 60529 |

/ | IP67/IP68 |

| Moisture Vapor Transmission |

ASTM E96 |

g/m2/24h | >5000 |

| Oleophobic Grade

|

AATCC 118 | Grade | ≥7 |

| Service Temperature

|

IEC 60068-2-14 | ℃ | -40 ℃ ~ 125 ℃ |

| ROHS

|

IEC 62321 | / | Meet ROHS Requirements

|

| PFOA & PFOS

|

US EPA 3550C & US EPA

8321B |

/ |

PFOA & PFOS Free

|

This series of membranes could equalize the pressure differentials of chemical containers which caused by temperature difference, altitude changes and releasing/consuming gases, in order to prevent container deformation and liquid leakage.

The membranes can be used in breathable liner and breathable plug products for chemicals packaging containers ,and be suitable for High-concentration Hazardous Chemicals, Low-concentration Household Chemicals, Agricultural Chemicals and other Special Chemicals.

Shelf life is five years from the date of receipt for this product as long as this product is stored in its original packaging in an environment below 80° F (27°C) and 60% RH.

All data above are typical data for the membrane raw material, for reference only, and should not be used as special data foroutgoing quality control.

All technical information and advice given here is based on Aynuo’s previous experiences and test results. Aynuo gives this information to the best of its knowledge, but assumes no legal responsibility. Customers are asked to check the suitability and usability in the specific application, since the performance of the product can only be judged when all necessary operating data are available.